TILED SHOWER WATERPROOFING SYSTEMS

Comparing traditional showers to bonded waterproof assemblies

By Sean Gerolimatos, director of research and development for Schluter Systems, and Don Recine, national builder accounts manager, Schluter Systems

For publication by White Paper

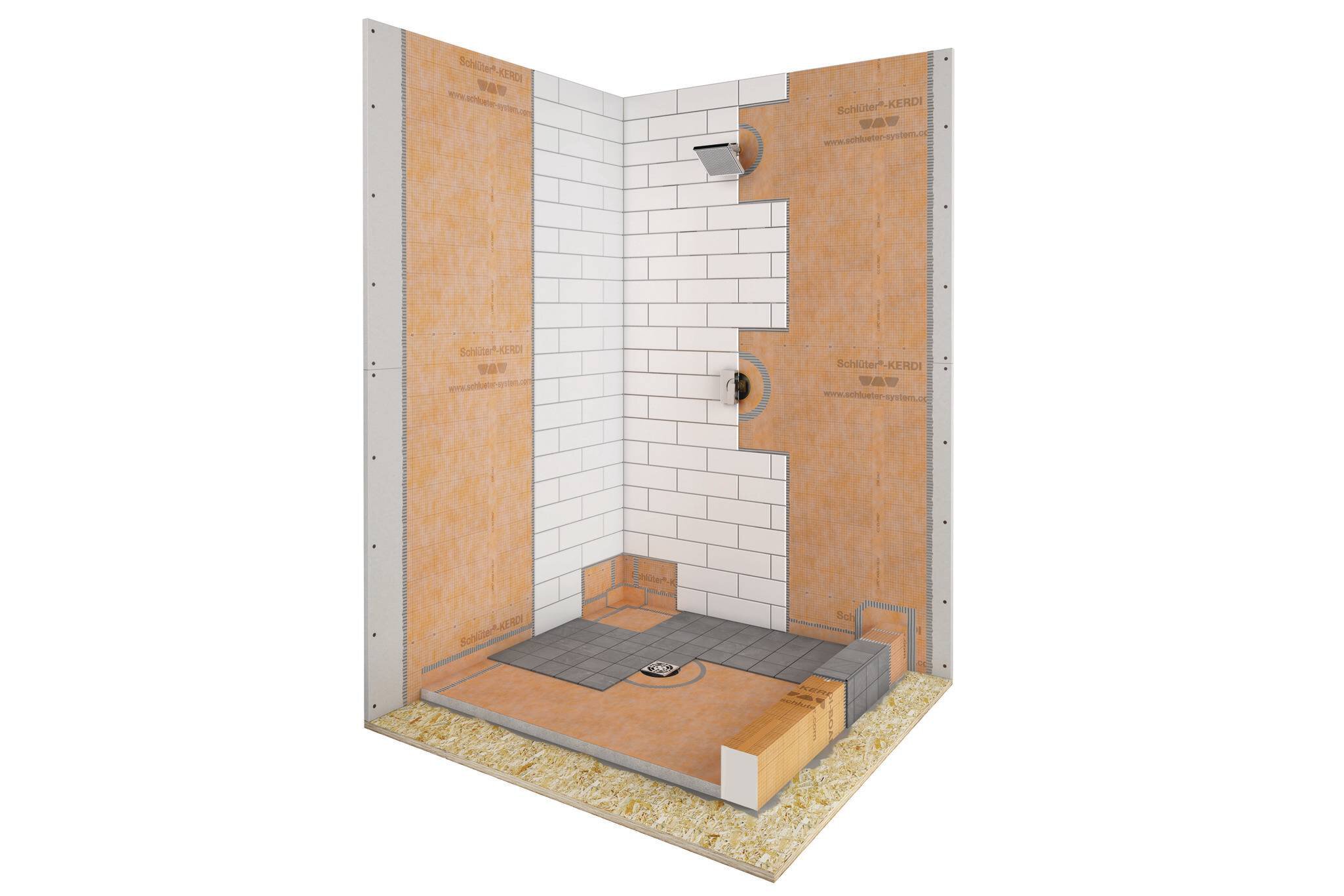

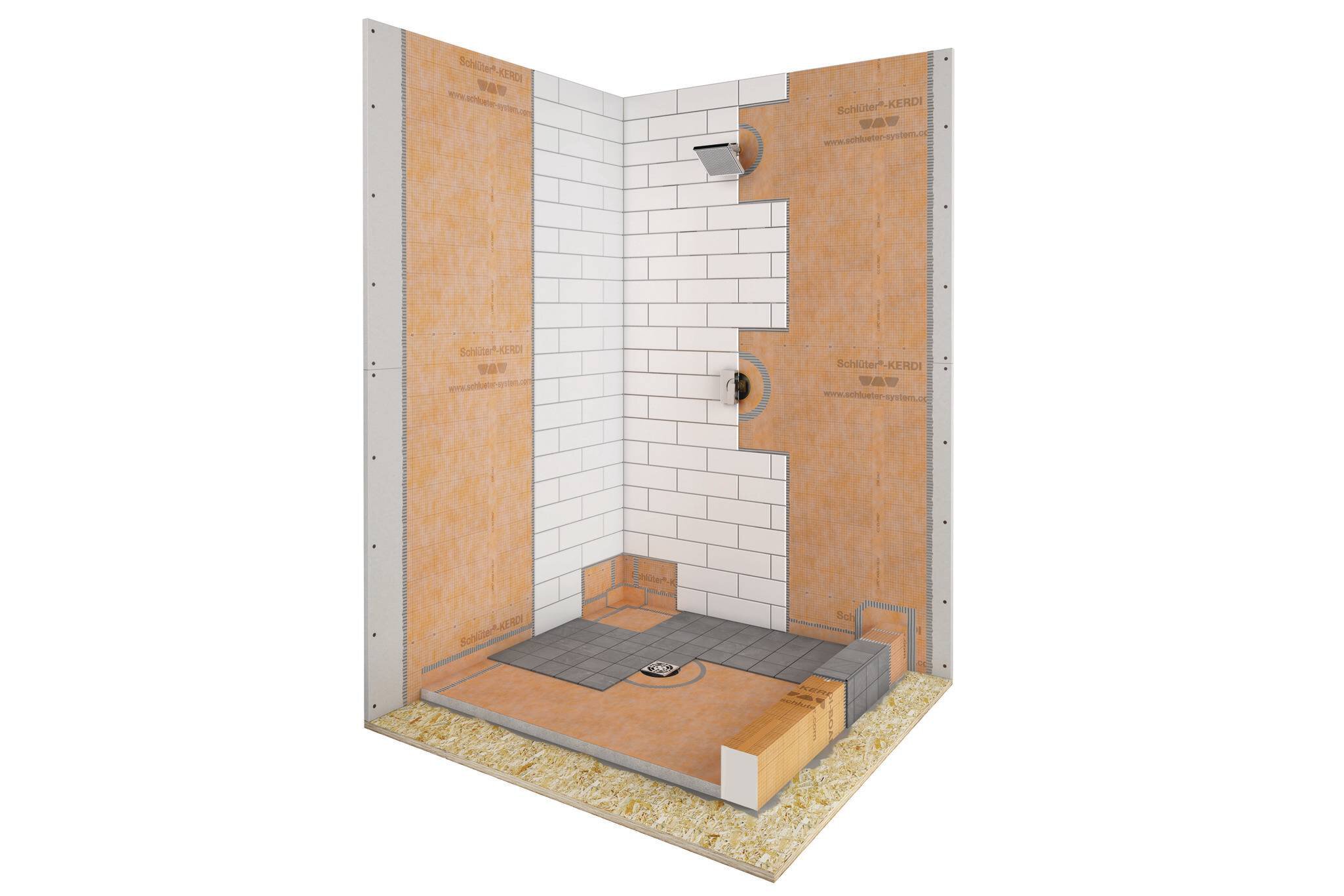

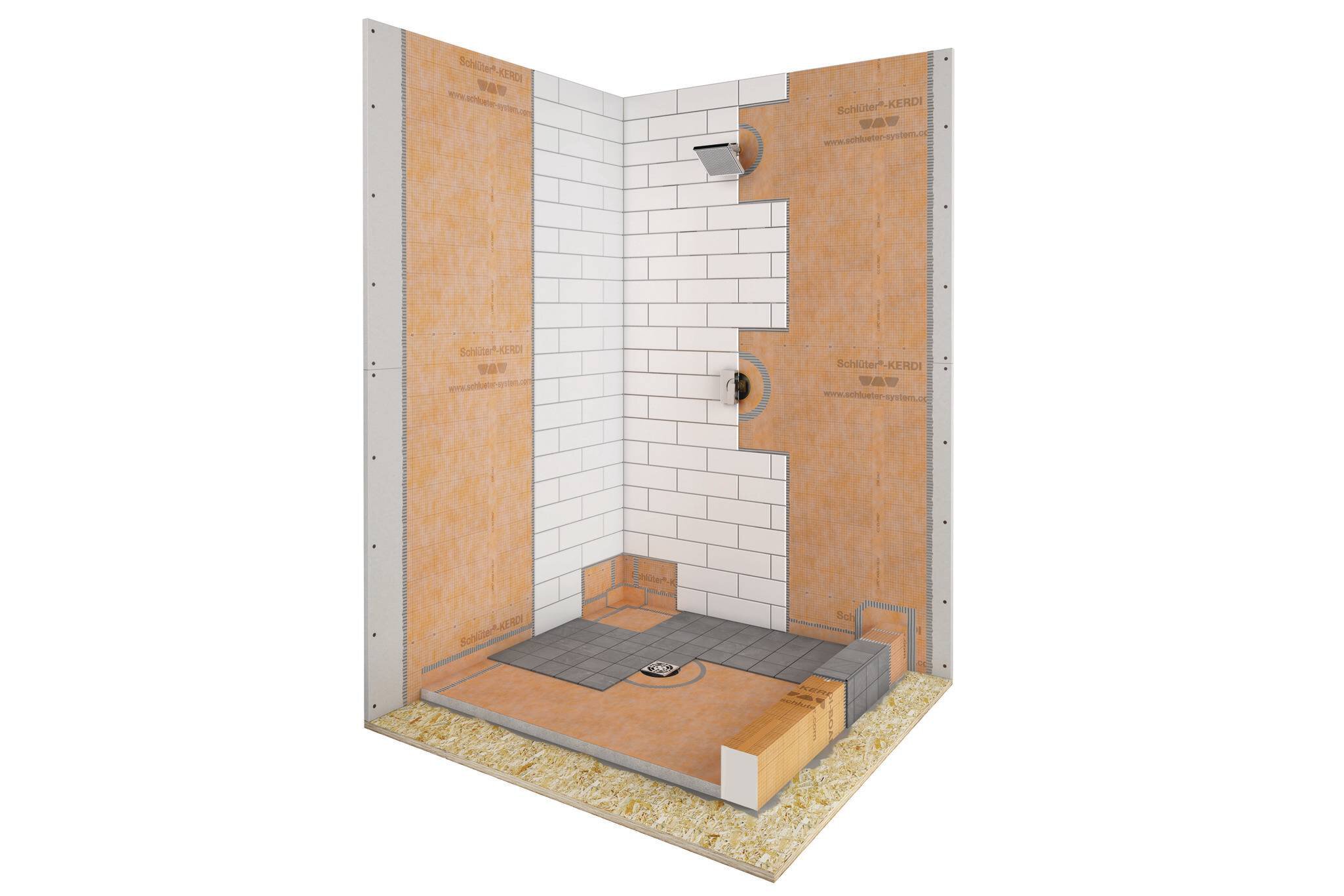

The Schluter®-KERDI-SHOWER-KIT contains all the components you need to easily create a waterproof and vapor-tight shower assembly. Available in a variety of shapes and configurations, all kits contain a shower tray, shower curb, KERDI waterproofing membrane and waterproofing strips, pre-formed corners, pipe seal, and mixing valve seal. With a variety of kits to choose from, kits without the drain and/or grate components are also available to allow for more flexibility in flange and grate selection. Explore all KERDI-SHOWER-KIT options here.

|

Many builders choose ceramic and stone tiles for the showers and bathtub surrounds in their homes because they are durable, easy to maintain, and hygienic – all features their home buyers covet. For these reasons, tiles are the ideal surface covering for wet areas. These coverings are not inherently waterproof, however, and must be installed in conjunction with a waterproofing system that effectively manages moisture to protect moisturesensitive building materials and control mold growth. |

Builders can choose from several different methods and systems for moisture management, but broadly speaking they fall into two categories. There are traditional shower assemblies, sometimes called water in/water out systems, and there are bonded waterproof shower assemblies, also known as sealed systems. Many factors must be considered when doing a complete review of systems, including final appearance of the tile installation, material cost, labor cost, ease or complexity of job-site scheduling, and post sales performance and call-backs.

A thorough comparison can provide some surprising results as costs in one area are often offset by equivalent savings in other areas. By examining each of the steps and components required to build a waterproof shower using the traditional method, versus a sealed system from Schluter Systems, it is possible to form a more complete picture of the options and their costs. The important stages of construction for a tiled shower are the shower base and curb, the walls, the drain assembly and most importantly the integration of these elements for a functional waterproof shower.

SHOWER BASE

THE TRADITIONAL METHOD

The traditional method for installing tiled shower assemblies creates what can be described as a water in/ water out system. It begins with the installation of a mortar bed over the subfloor that is sloped to the weep holes in the drain. A waterproofing membrane, typically referred to as a pan liner, is subsequently placed over this "pre-slope" and clamped into the drain. Pan liners may consist of lead, copper, polyvinyl chloride (PVC) or chlorinated polyethylene (CPE). Some regions of the country also employ hot mop systems where layers of asphalt and roofing felt are applied to build-up a pan liner.

Pan liners are carried up to a height of at least 3" above the finished height of the curb. The liner must be wrapped over the typically wood, masonry, or concrete curb itself as well. Because pan liners are not designed to allow for the direct application of tile a mortar bed must be installed to provide load distribution and a bonding surface for the tile. The mortar bed is sloped toward the drain, and tiles are installed using thin-set mortar. Pea gravel, tile spacers, or other means of protection should be placed around the weep holes of the drain before installing the mortar bed to prevent blockage of the water reaching this secondary outlet. The Tile Council of North America (TCNA) Handbook for Ceramic, Glass, and Stone Tile Installation includes various methods for the installation of tiled showers in the traditional manner (e.g., B414, B415, etc.) and serves as a valuable reference to the installer.

BONDED SYSTEMS, INCLUDING THE SCHLUTER SYSTEM

In the mid-to-late 1980s, manufacturers introduced bonded waterproof membranes, which are adhered to the substrate and allow for the direct application of tile. These membranes include sheet membranes, which are bonded to the substrate with thin-set mortar or other adhesives, 2 WHITE PAPER WHITE PAPER 3 and liquid-applied products, which are spread over the substrate and allowed to dry/cure to form the membrane. Many of the liquid-applied products require multiple coats with drying time in between. The minimum performance criteria for bonded waterproof membranes are established in the ANSI A118.10 standard. The Schluter system includes a modified polyethylene (PEVA) sheet-applied membrane with a bonding fleece embedded on both sides.

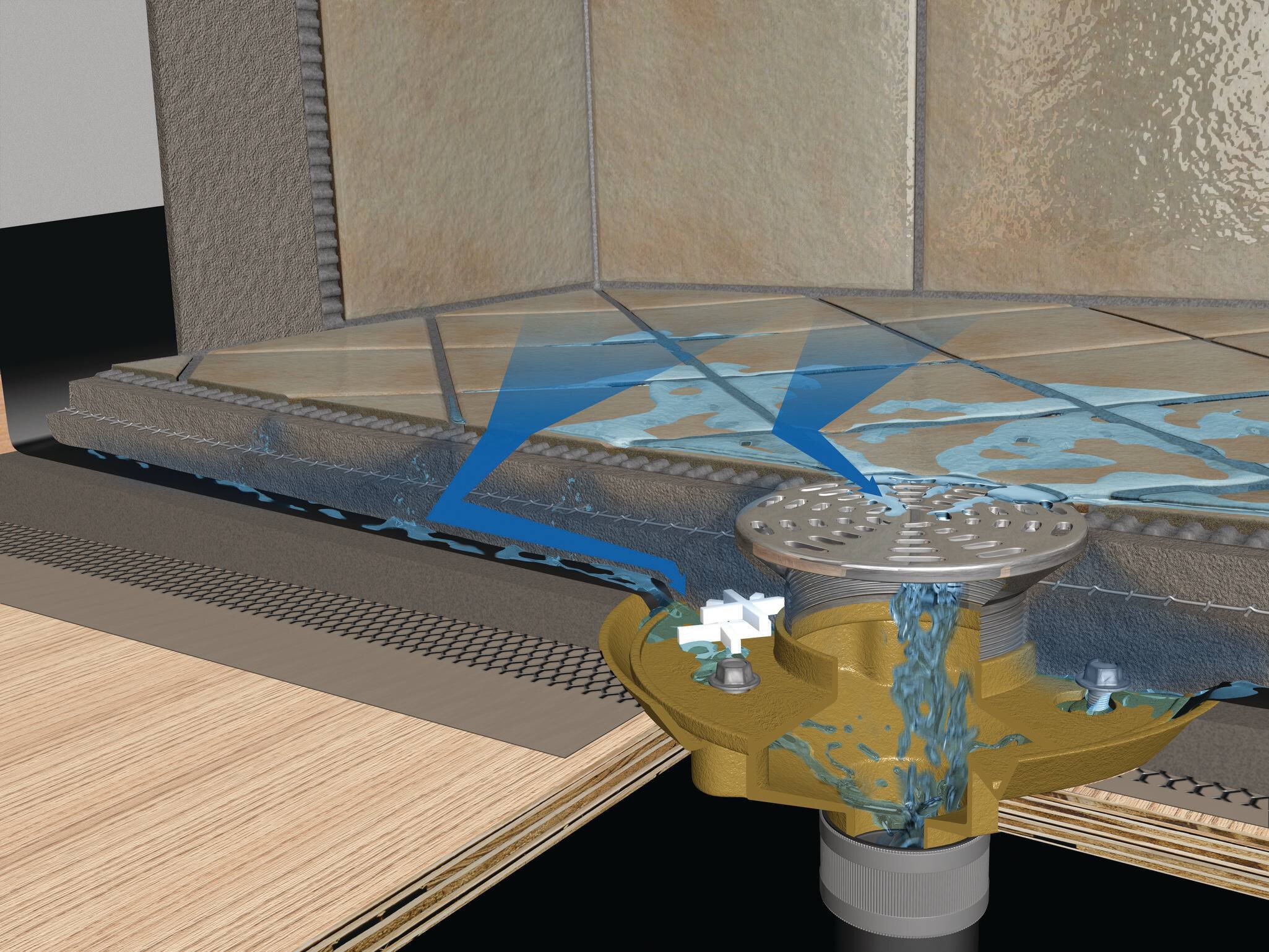

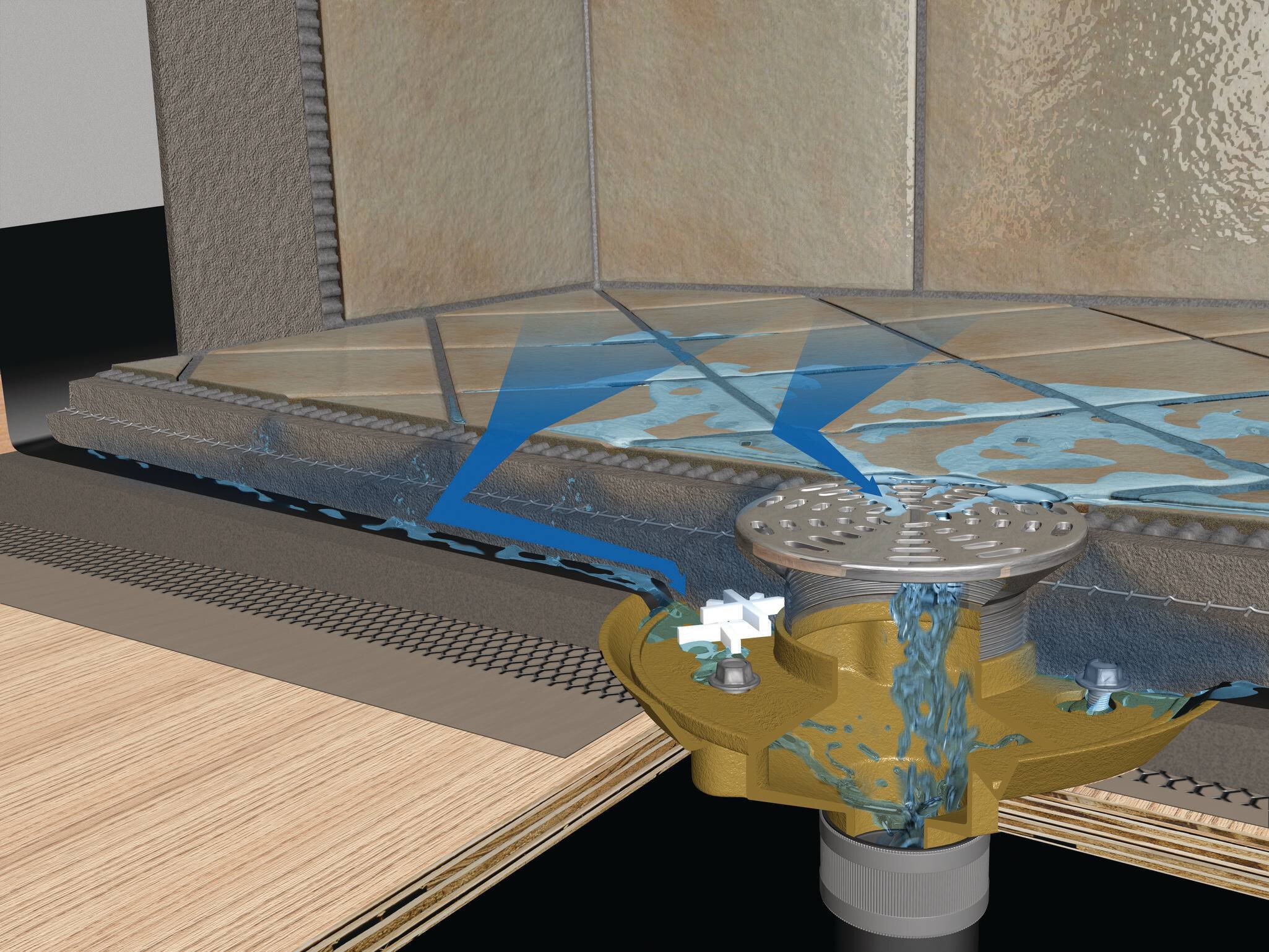

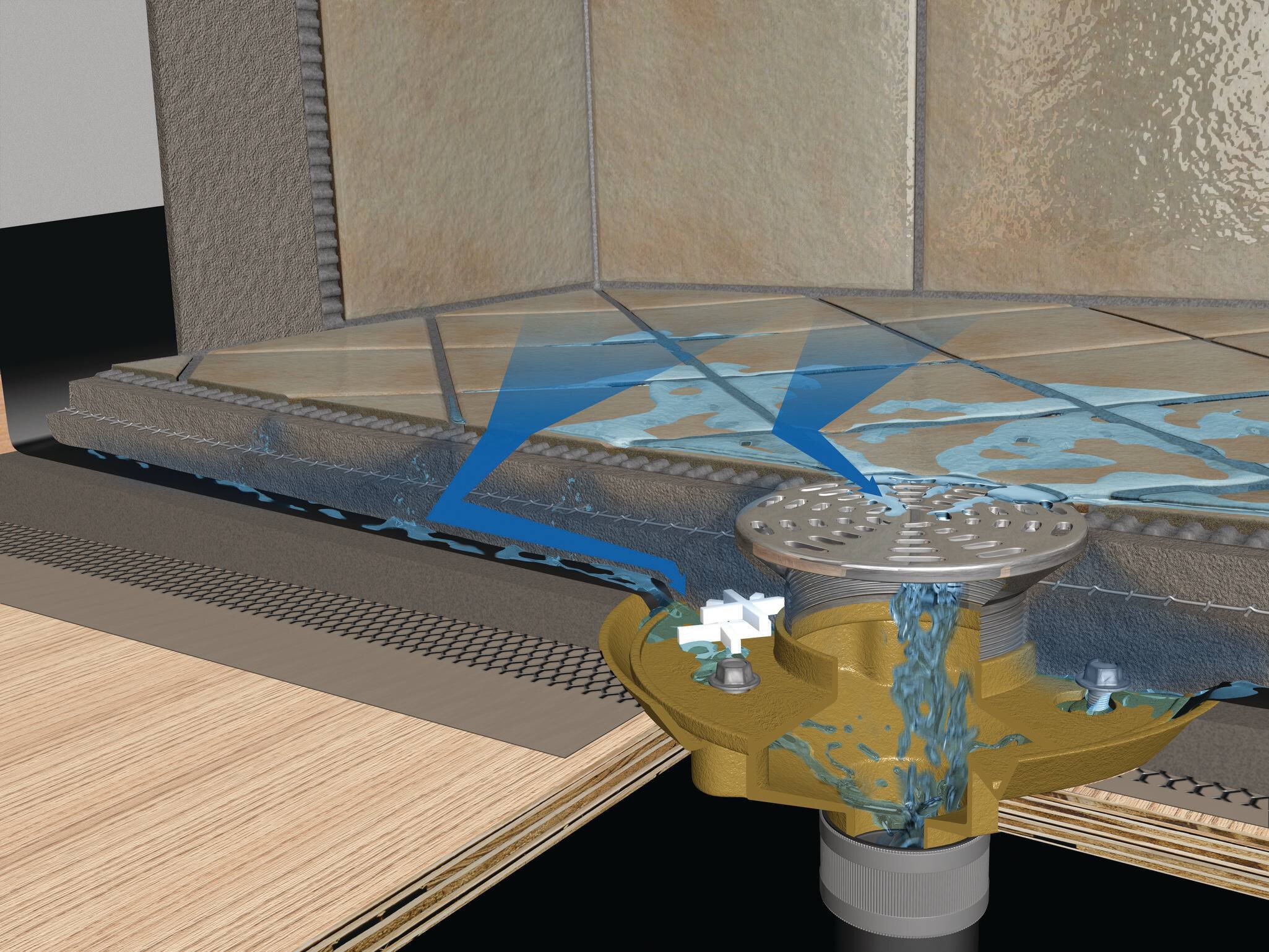

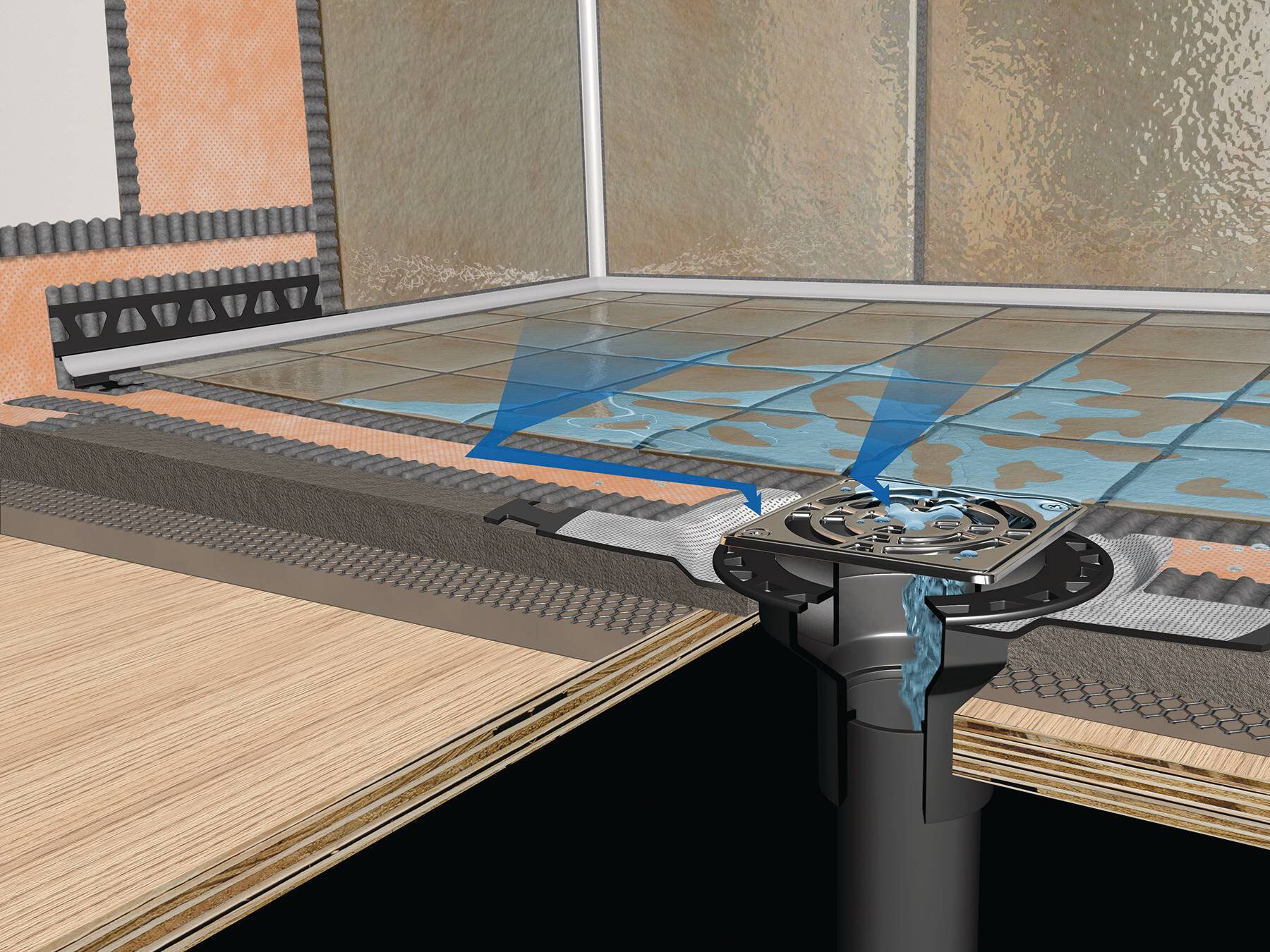

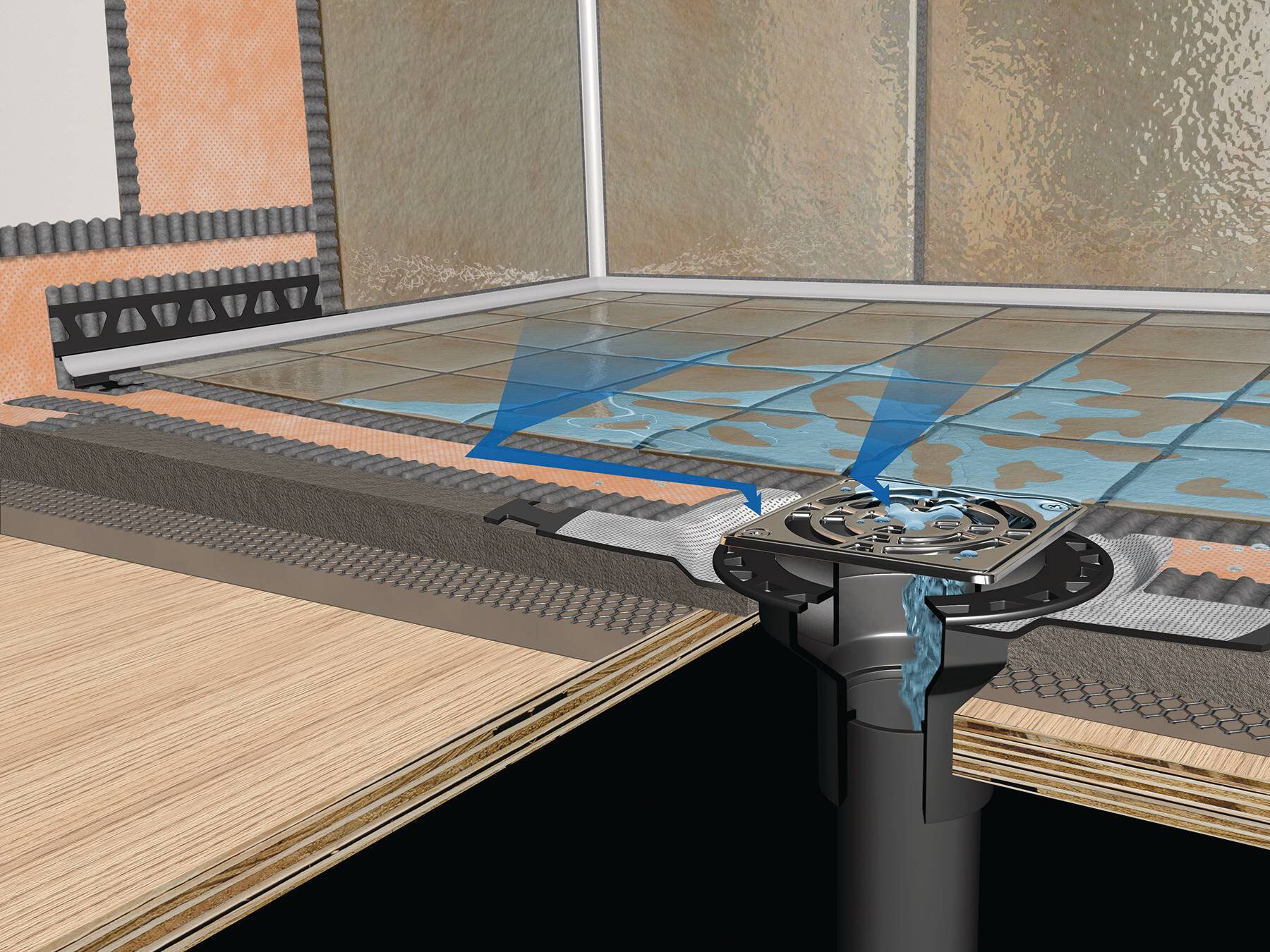

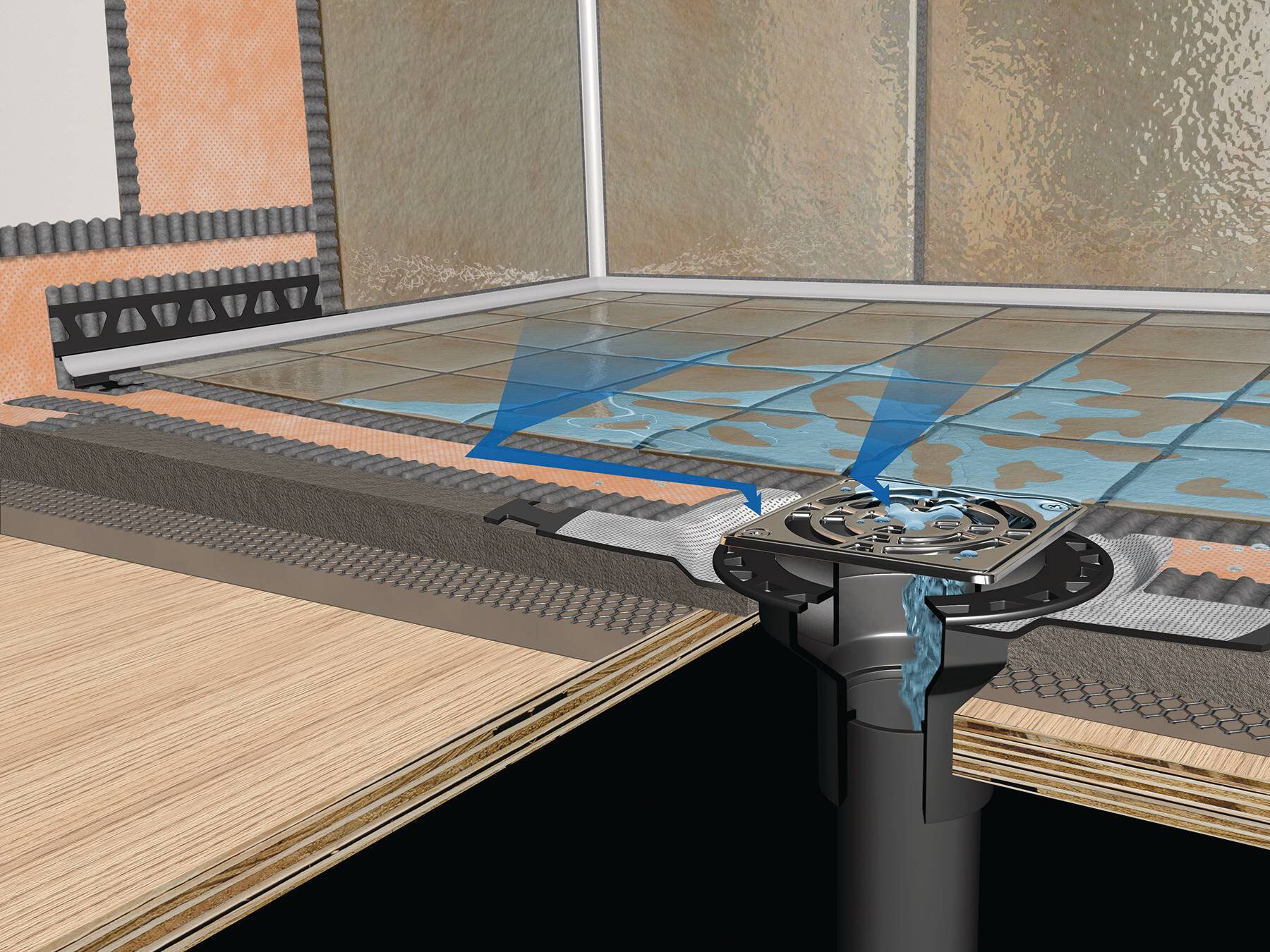

The membrane is installed over a sloped base, either a prefabricated EPS foam tray or a mortar bed, and shower drain with integrated bonding flange using thin-set mortar. Drains that feature integrated bonding flanges provide a large contact area to allow for a watertight connection between the membrane and the top of the drain assembly. In the event that a traditional clamping drain has already been installed by the plumber, the Schluter system includes an adaptor kit that can be used to quickly and costeffectively convert the clamping drain into an integrated bonding flange drain. Methods B422 and B422C in the TCNA Handbook demonstrate the use of a bonded waterproof membrane and integrated bonding flange.

COMPARISON

Each component described in the Traditional Method above is essential to the function of the overall system. For example, a common error is to ignore the pre-slope installation and place the pan liner directly over the flat subfloor. Since the tile covering itself is not waterproof, moisture will infiltrate the mortar bed; if the pan liner is not placed on a sloped substrate, the system will not effectively drain the water to the weep holes in the drain, creating a permanently saturated mortar bed. This increases the potential for efflorescence, grout discoloration, and mold growth within the system. Even with proper installation, eventually the weep holes can become clogged due to soap, shampoo, body lotions, etc. Moisture still accumulates, creating a saturated mortar bed and causing the same problems of grout discoloration, odors and potential mold growth. Another all too common mistake is to penetrate the pan liner by using nails to fasten backer board panels to the curb or to the studs on the shower walls. Even small penetrations in a pan liner can lead to large leaks and damage to the surrounding materials.

When the Schluter system is used, the membrane is applied topically (on the surface), with all water directed into the top of the drain. The resulting assembly does not permit moisture penetration into a mortar bed, allowing the assembly to dry completely between uses and eliminating the potential for mold growth in the system. Furthermore, the builder doesn’t need to pay for a pre-slope or to supply and install the plumber’s liner. Depending on the market and methods used, these costs can be significant, easily adding up to hundreds of dollars. In some markets, there is even an additional "trip charge" to be paid by the builder to the tile contractor to install the pre-slope prior to the liner. Using the adaptor kit with the clamping drain allows the builder to continue with the production schedule without interruptions. The plumber roughs in the entire house making all the watertight connections before the tile contractor arrives to complete the shower base assembly.

The Schluter system provides the option of using a preformed shower tray with the slope built in and waterproof membrane applied at the factory. The use of such a tray eliminates the need to build a mortar bed, a process that can be particularly challenging for larger shower floors. The preformed tray makes installation much faster as it eliminates the required drying time for the mortar bed, and it guarantees a uniform slope on the shower floor.

SHOWER WALLS

THE TRADITIONAL METHOD

Most wall assemblies require a vapor retarder, such as roofing felt, reinforced asphalt paper, polyethylene sheeting, etc. installed over the studs and lapped over the pan liner. The builder typically has tile backer board (e.g., CBU or fiber-cement board) supplied and installed by the gypsum board installer or the tile contractor. In some cases, a trowel-applied or roll-on waterproofing membrane is installed over the backer board.

THE SCHLUTER SYSTEM

Standard gypsum board may be installed in the shower. A specific tile backer board is not required which saves the builder cost. The tile installer then applies the sheet waterproofing membrane in the same manner (topically) as on the shower base and overlaps the floor-to-wall transition.

COMPARISON

Typical tile backer boards used in the Traditional Method, such as CBU or fiber-cement board, are water-resistant but not waterproof. Moisture will infiltrate the board and seep down along the vapor retarder into the mortar base. Even when a waterproof backer is used or the board is covered with a waterproofing membrane, it doesn’t address the shower base, where moisture will still infiltrate the mortar bed.

Using the Schluter system creates an entirely waterproof envelope directly behind the tile. It also provides savings for the builder because regular gypsum board can be used throughout the entire home. There is no special backer board to purchase or install, so the drywall installation crew can treat all areas of the home exactly the same. This allows them to work more quickly and save time on the production schedule. The builder also saves the cost of the more expensive backer board for shower and tub surround areas.

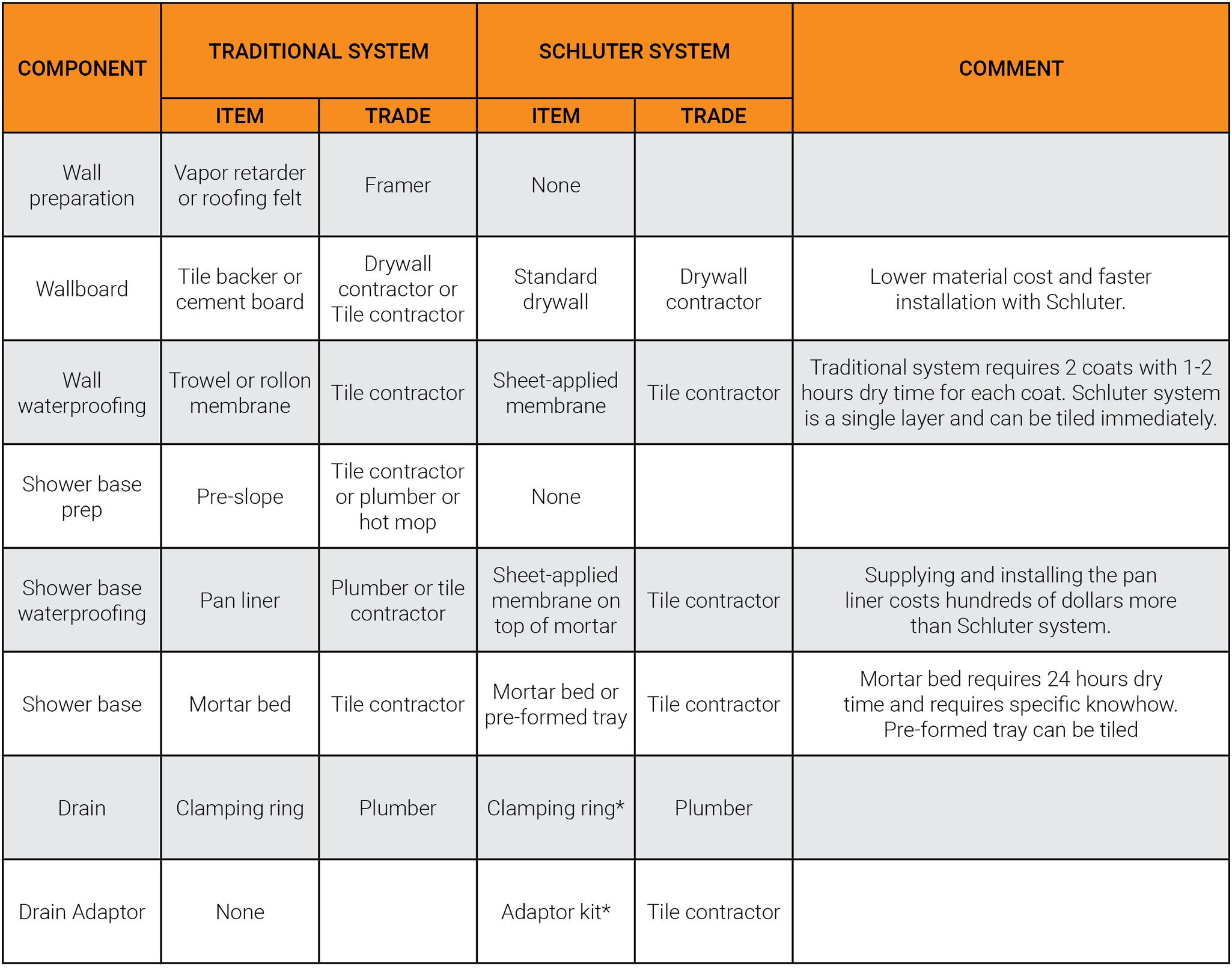

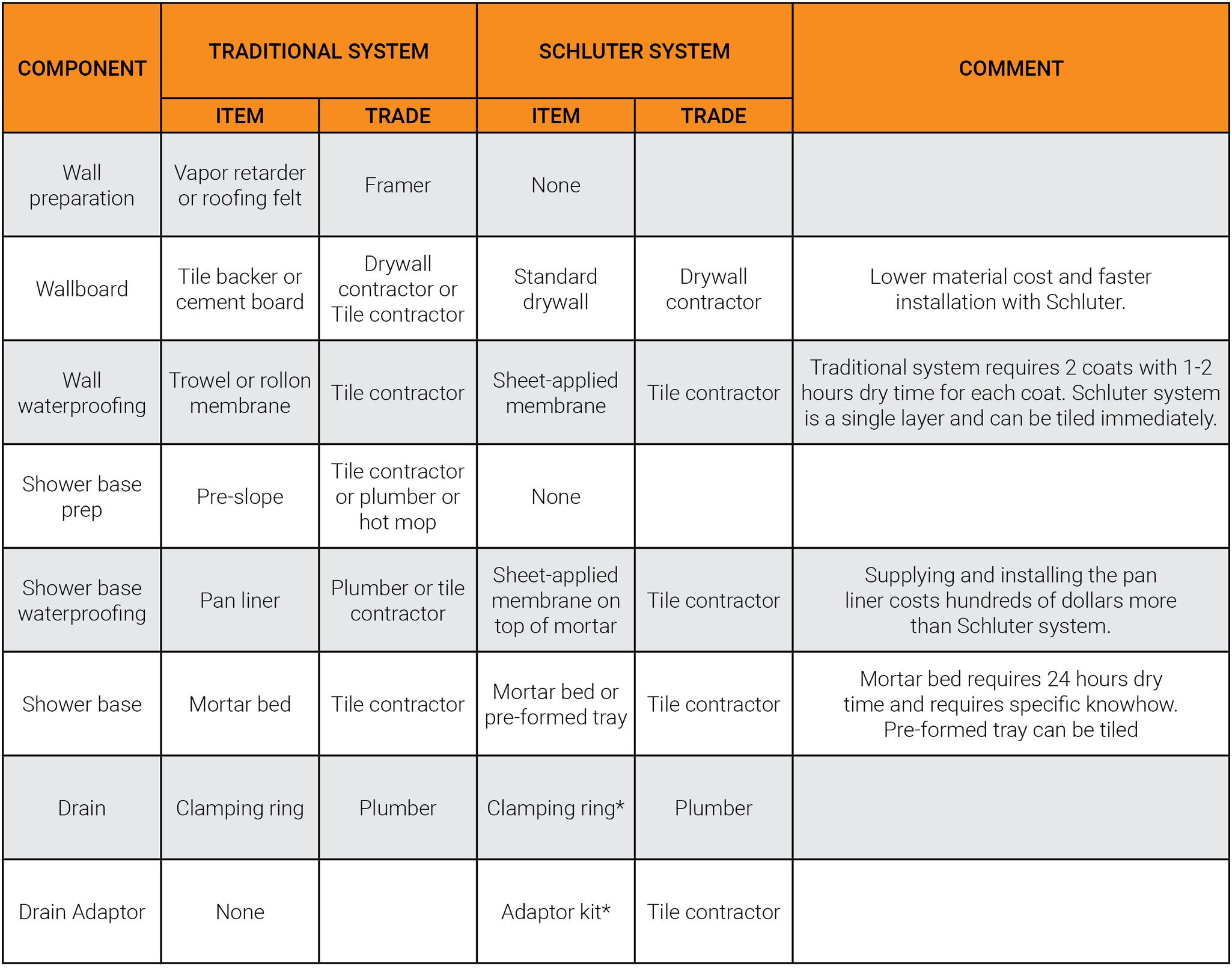

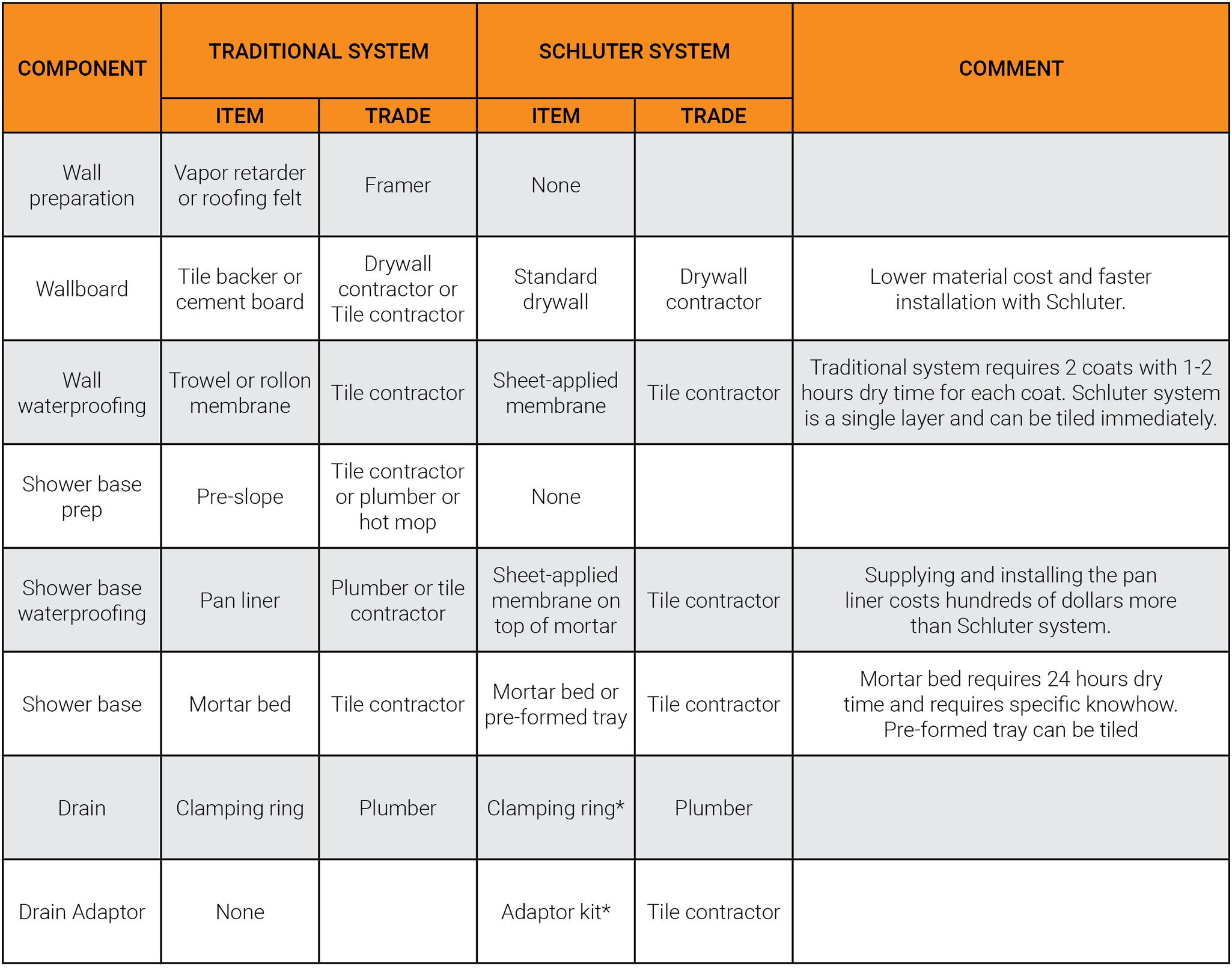

TRADITIONAL SYSTEM VS. SCHLUTER SYSTEM

This table shows the materials required and the trade responsible for each step of shower construction.

The traditional system requires more trades to visit the site more times than the Schluter system. This approach can create crossover of trades and scheduling challenges and delays. With the Schluter system the drywall contractor and plumber are each required to work on the shower area only once and on their regular schedule. From that point forward the tile contractor owns the entire installation including all aspects of waterproofing and tile installation.

* The Schluter system is designed to work with a top mounted drain with a bonding flange instead of a clamping ring drain. The Schluter drain could be installed by the plumber or the tile contractor and connected to a stub that has been installed by the plumber. Some builders prefer to use the clamping ring drain with the adaptor kit because it suits their site scheduling better and eliminates trade crossover.

FINISHED SHOWER

THE TRADITIONAL METHOD

The traditional method of shower construction, especially with respect to the base, is designed in a way that allows water into the tile substrate. With regular use of the shower the mortar bed can remain saturated, particularly if pre-slope installation is ignored or the weep holes become clogged, thus increasing the potential for efflorescence and mold growth within the system. There are also inherent challenges in creating thorough waterproofing, especially around the curb. The result is compromised performance for many of these showers which can often lead to costly callbacks and a damaged reputation for the builder.

THE SCHLUTER SYSTEM

The Schluter system assembly provides complete moisture management as it does not permit moisture to penetrate into the tile substrate, either the base or the walls, and allows the assembly to dry completely between uses. It is an integrated system that is simple and easy to install, which in turn prevents leaks and reduces the potential for efflorescence and mold growth in the system. Cost savings are realized through a faster, more efficient installation method and dramatically reduced call backs.

Note Regarding Water Vapor

It is important to consider that water exists as both liquid and vapor in showers, and must be managed in both forms. The ANSI A118.10 standard for bonded waterproof membranes was developed to provide a framework for determining the suitability of these products to serve as barriers to liquid water only. As such, the standard does not include a minimum criterion to establish the ability of products to limit vapor transmission.

Water vapor permeance is a measure of how quickly water vapor is transmitted through a material and can be determined according to the ASTM E96 Standard Test Method for Water Vapor Transmission of Materials. The higher the vapor permeance, the less effective a material is at slowing vapor transmission.

There is no universal requirement for vapor permeance of membranes in the building industry. The environmental conditions (i.e., differences in temperature and relative humidity), building materials, etc., and relevant field experience will determine the appropriate membrane performance for a given application. The consensus within the tile industry in North America has been that a vapor permeance of 1.0 perm or less will manage vapor effectively in showers. Schluter®-Systems’ Kerdi membrane has a vapor permeance of 0.9 so it comfortably meets this requirement.