Sustainable Install with Schluter Systems at Montreal REM Train Station

Architects:

Bisson Fortin - Lemay - Perkins&Will

Engineering & Construction Partnership:

NOUVLR

Tile installation by:

Les Tuiles Carrasqueira Casimiro (T.C.C.) Inc.

Date & location:

2024 Montreal, QC

About

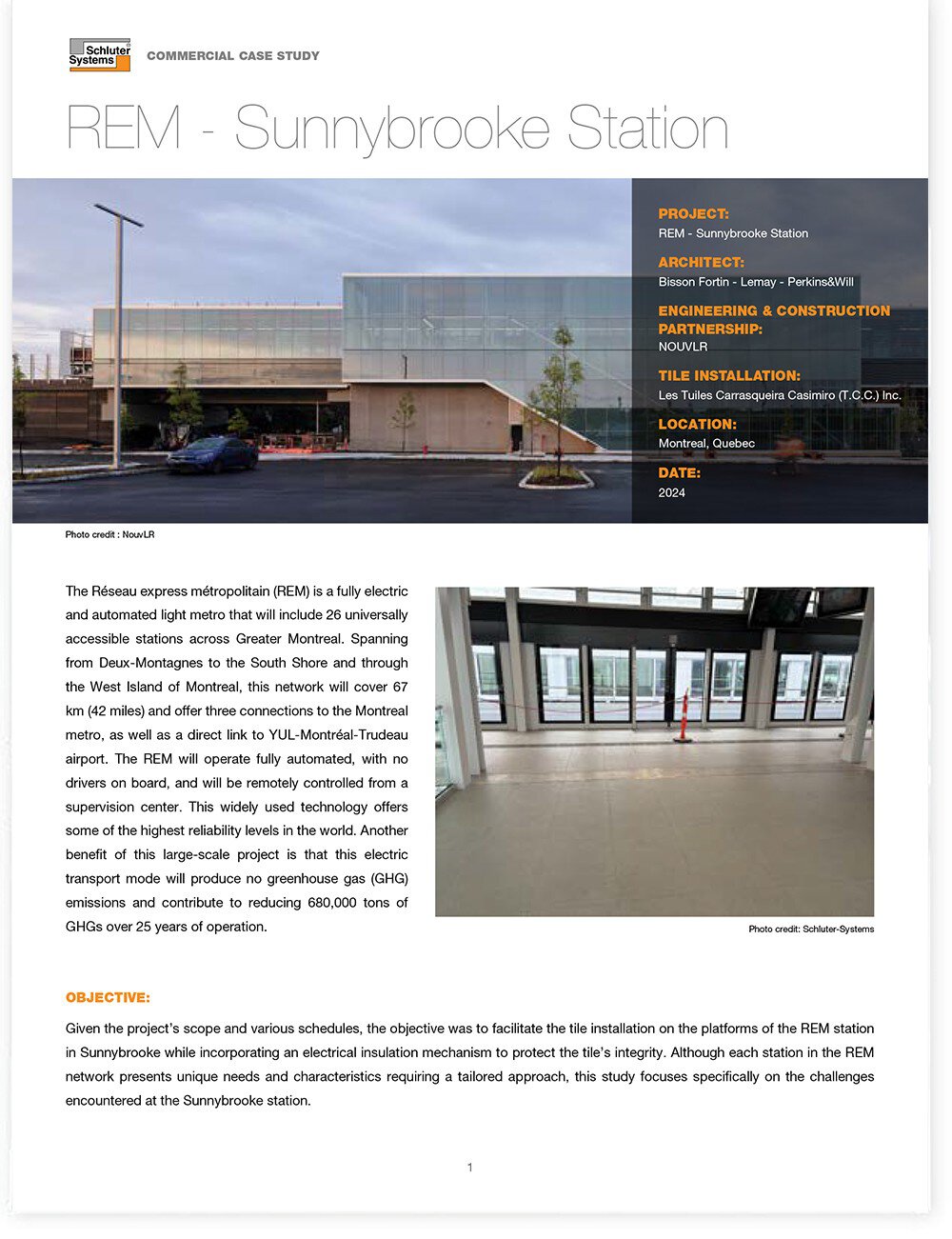

The Réseau express métropolitain (REM) is a fully electric and automated light metro that will include 26 universally accessible stations across Greater Montreal. Spanning from Deux-Montagnes to the South Shore and through the West Island of Montreal, this network will cover 67 km (42 miles) and offer three connections to the Montreal metro, as well as a direct link to YUL-Montréal-Trudeau airport.

The REM will operate fully automated, with no drivers on board, and will be remotely controlled from a supervision center. This widely used technology offers some of the highest reliability levels in the world.

Another benefit of this large-scale project is that this electric transport mode will produce no greenhouse gas (GHG) emissions and contribute to reducing 680,000 tons of GHGs over 25 years of operation.

Objective

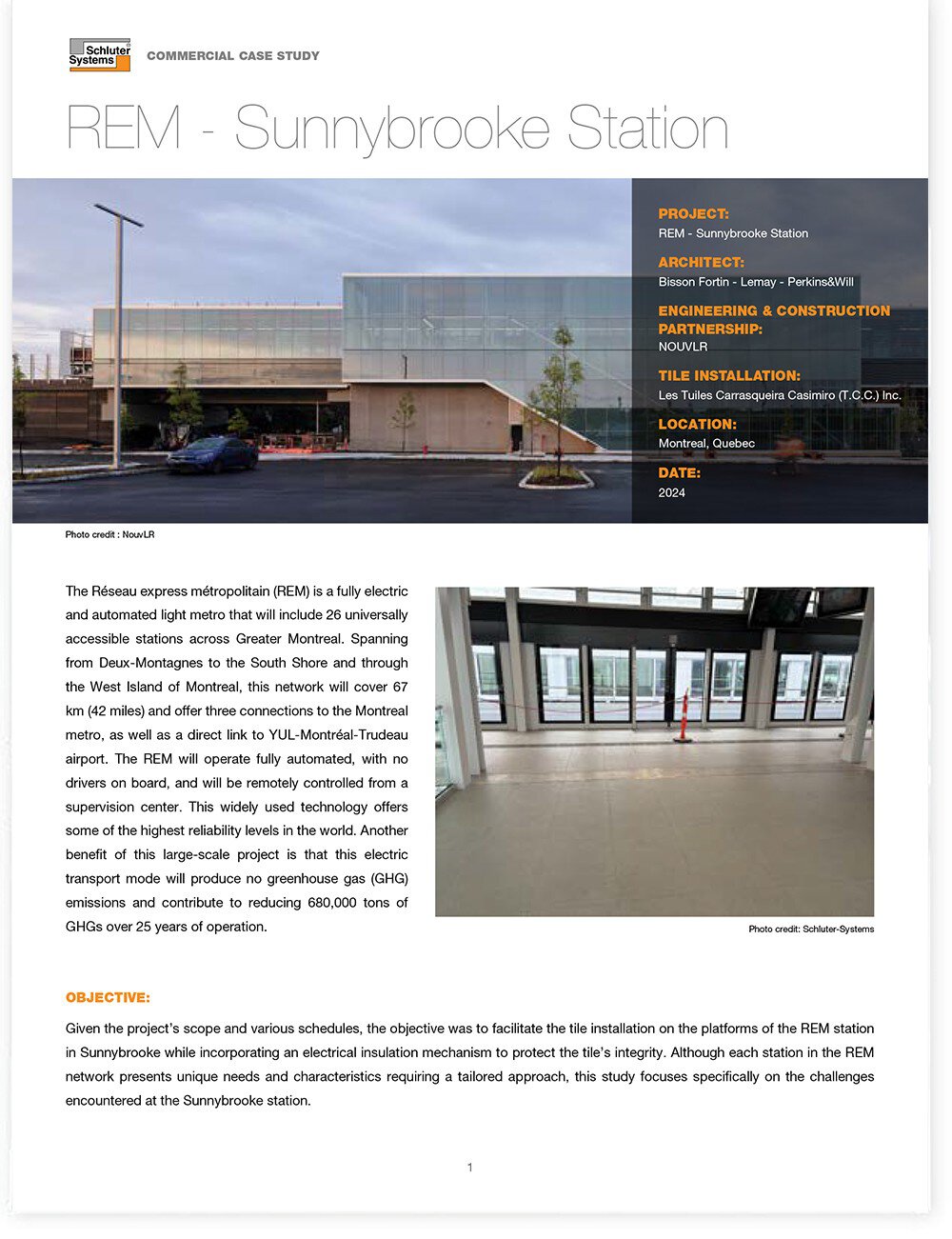

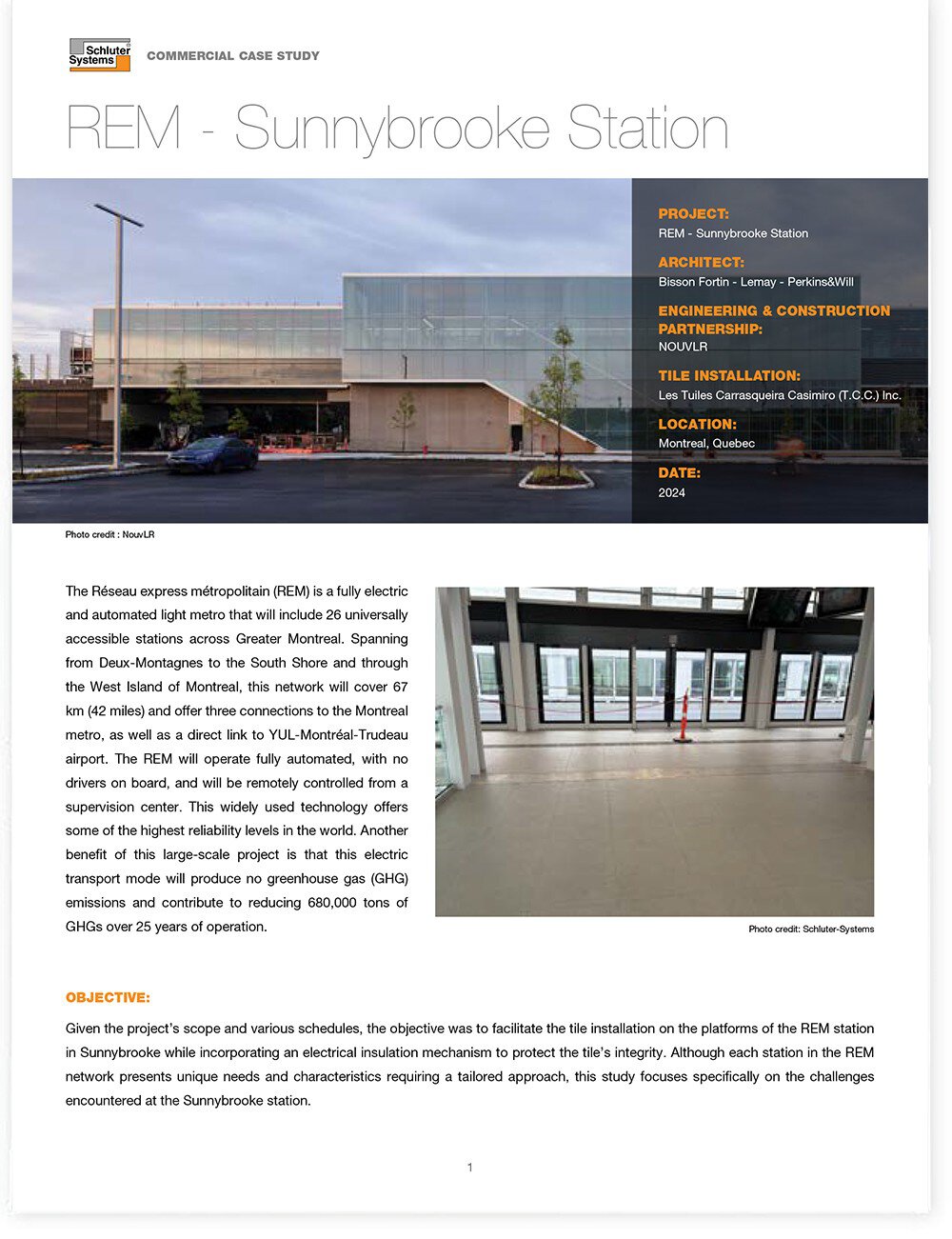

Given the project's scope and various schedules, the objective was to facilitate the tile installation on the platforms of the REM station in Sunnybrooke while incorporating an electrical insulation mechanism to protect the tile's integrity. Although each station in the REM network presents unique needs and characteristics requiring a tailored approach, this study focuses specifically on the challenges encountered at the Sunnybrooke station.

Challenge

One major challenge of this project was ensuring the durability of the installation in an environment subject to heavy and constant traffic. This required a robust and long-lasting solution capable of withstanding daily use without compromising material integrity. Additionally, it was essential to ensure that the assembly met strict dielectric strength requirements to guarantee long-term performance and electrical safety. This was particularly crucial because any failures could lead to significant consequences. Moreover, during laboratory selection, an additional test was required to meet the dielectric strength requirements, particularly the resistance factor.

Solution

Given the extremely high traffic expected on the REM platform, it was important to ensure the installation's performance. The DITRA membrane was chosen to enable a compliant installation capable of managing differential movements between porcelain tiles and the underlying structure. The uncoupling function provided by the DITRA membrane is essential in this case; it helps prevent cracks and tile delamination by isolating them from the subfloor.

The membrane's quick installation also facilitated meeting the tight deadlines characteristic of a large-scale project. To ensure the platform assembly's waterproofing, KERDI-BAND was installed at the DITRA membrane joints. ALL-SET thin-set was used to ensure optimal adherence of the tiled assembly, thereby enhancing the installation's solidity and longevity.

In collaboration with the testing laboratory, specific dielectric strength tests were conducted, including the additional resistance factor required to meet the project standards. This approach validated the installation's long-term performance while adhering to the project's strict requirements.

Result

The installation was successfully completed, meeting durability requirements in a high-traffic environment. Conductivity and resistance factor tests confirmed compliance, ensuring optimal durability and performance.

Products used