Comfort and Control: DITRA-HEAT-DUO at Schluter’s 500,000 sq. ft. DFW Facility

The project:

Schluter Distribution Center

Architects:

Alliance Architects

Mechanical & Electrical engineering:

JJA INC

Tile contractor:

Wadleigh Tile

Date & location:

2020 Dallas-Fort Worth, TX

About

The Schluter facility in Dallas-Fort Worth (DFW) is a cutting-edge, 500,000-square-foot complex that includes a new distribution, office, and training center. Strategically chosen for its location, the facility enhances the turnaround time on orders, ensuring that most of the country can be reached within 72 hours after receiving a purchase order.

Objective

The main goal of the DITRA-HEAT-DUO installation was to create a warm and comfortable environment for employees and visitors. The project also aimed to showcase how electric floor warming can be effectively implemented in a large commercial space.

Challenges

A major challenge of the installation was the extensive size of the project, covering 25,000 square feet of floor space. The system required significant hardware, including over 140 thermostats and power modules, along with more than 160 temperature sensors. Ensuring seamless integration with the HVAC system and organizing all components for optimal functionality was also a significant task.

Solutions

To manage the scale of the installation, a centralized control wall system was developed, incorporating over 140 thermostats and power modules. These were organized into three strategically placed control locations that aligned with the HVAC system. This configuration allowed for efficient monitoring and easy maintenance of the system, resulting in uncluttered walls and seamless operation. Interchangeable temperature sensors were installed for flexible control and temperature reading.

Key areas equipped with DITRA-HEAT-DUO included:

- Training Room – 2665 sq. ft.

- Hands-On Area – 2525 sq. ft.

- Training Lounge & Cafeteria – 3065 sq. ft.

The system demonstrated versatility by utilizing multiple power supplies (120 V, 240 V, and 208 V) and supporting various floor coverings such as tile and laminate, installed both indoors and in exterior-facing spaces.

Result

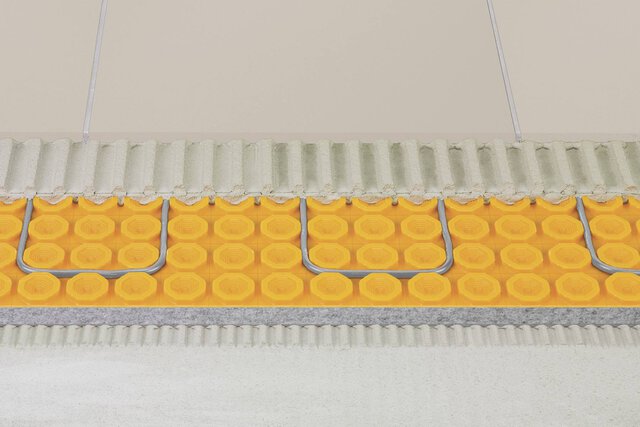

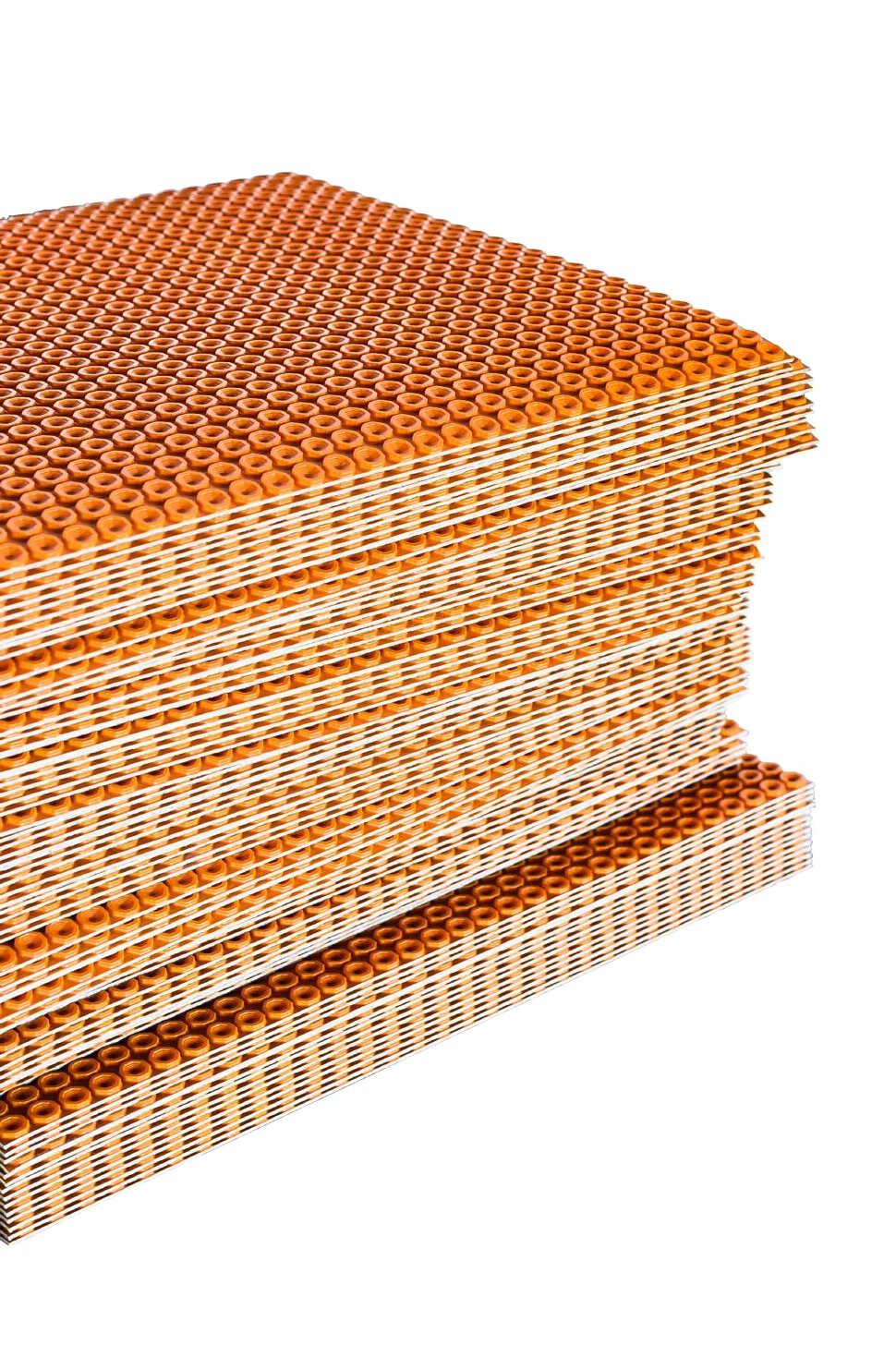

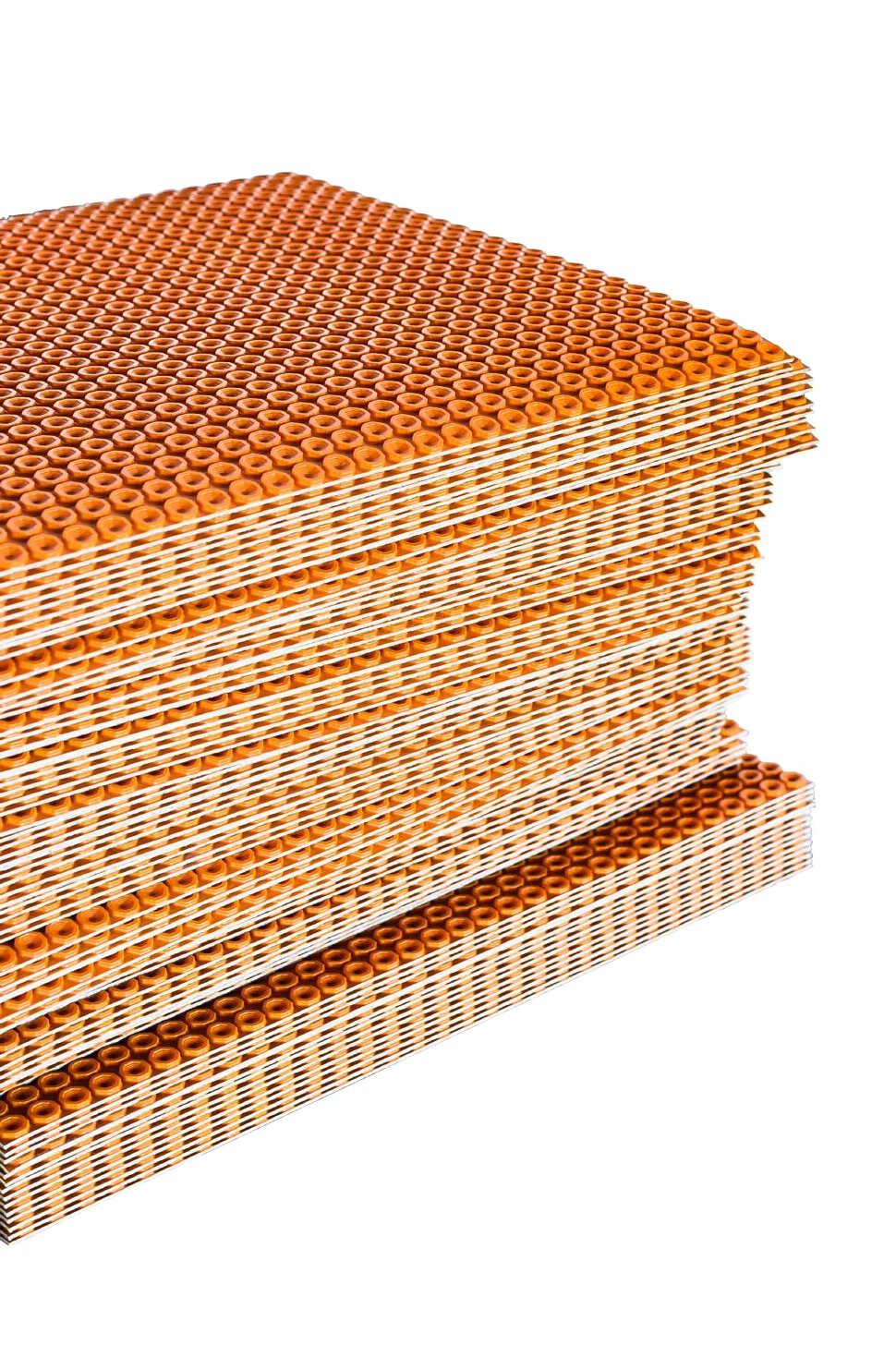

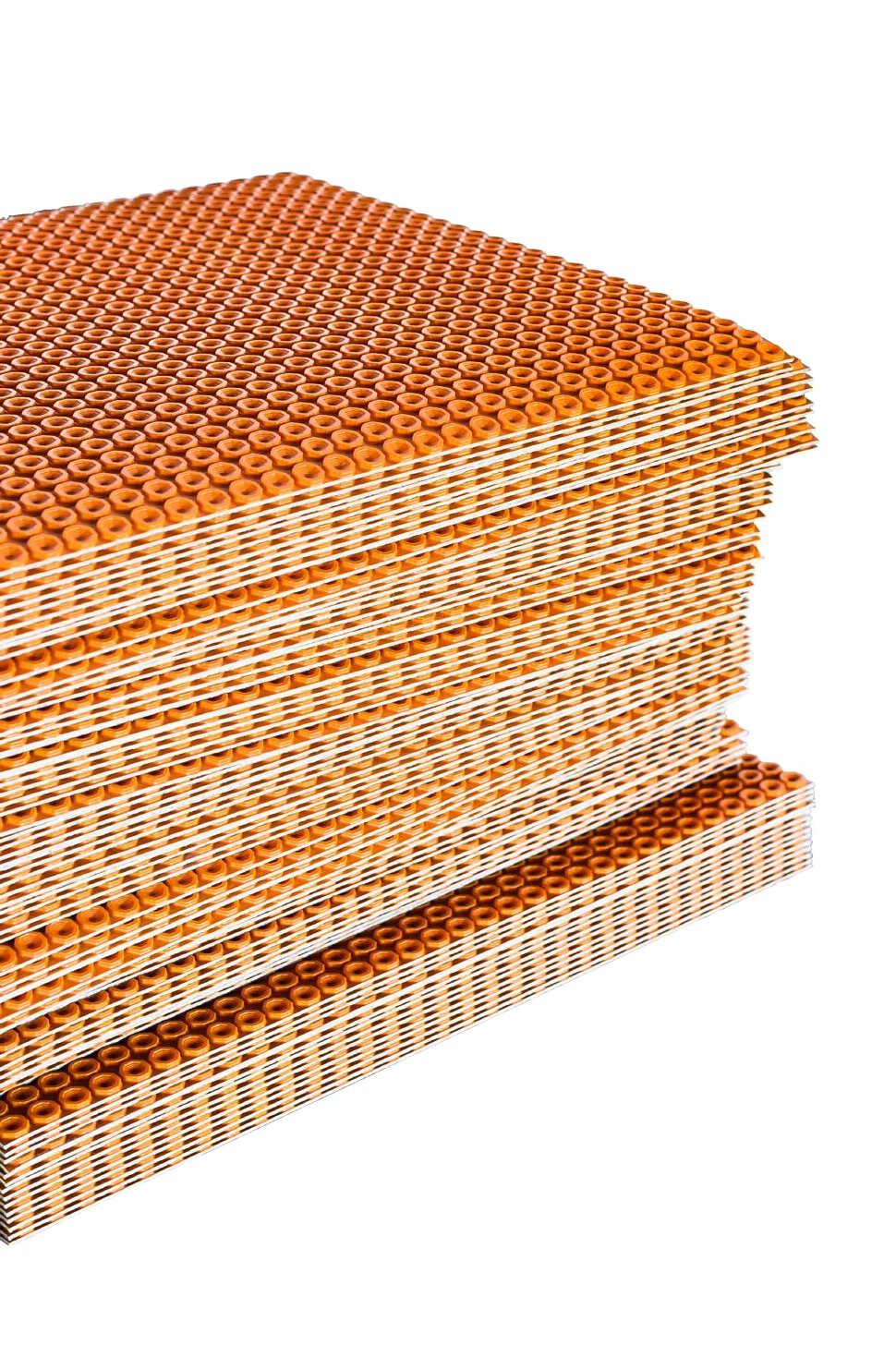

The DFW facility installation successfully demonstrated that electric floor warming can provide substantial benefits even in warm climates. The DITRA-HEAT-DUO system provided consistent, fast-response floor heating that could be controlled in specific zones, eliminating cold spots and enhancing overall comfort. Its lightweight, thin assembly also contributed to a faster build time compared to more traditional heating methods. The system's dust- and allergen-free operation further supported a healthier environment for employees and visitors.

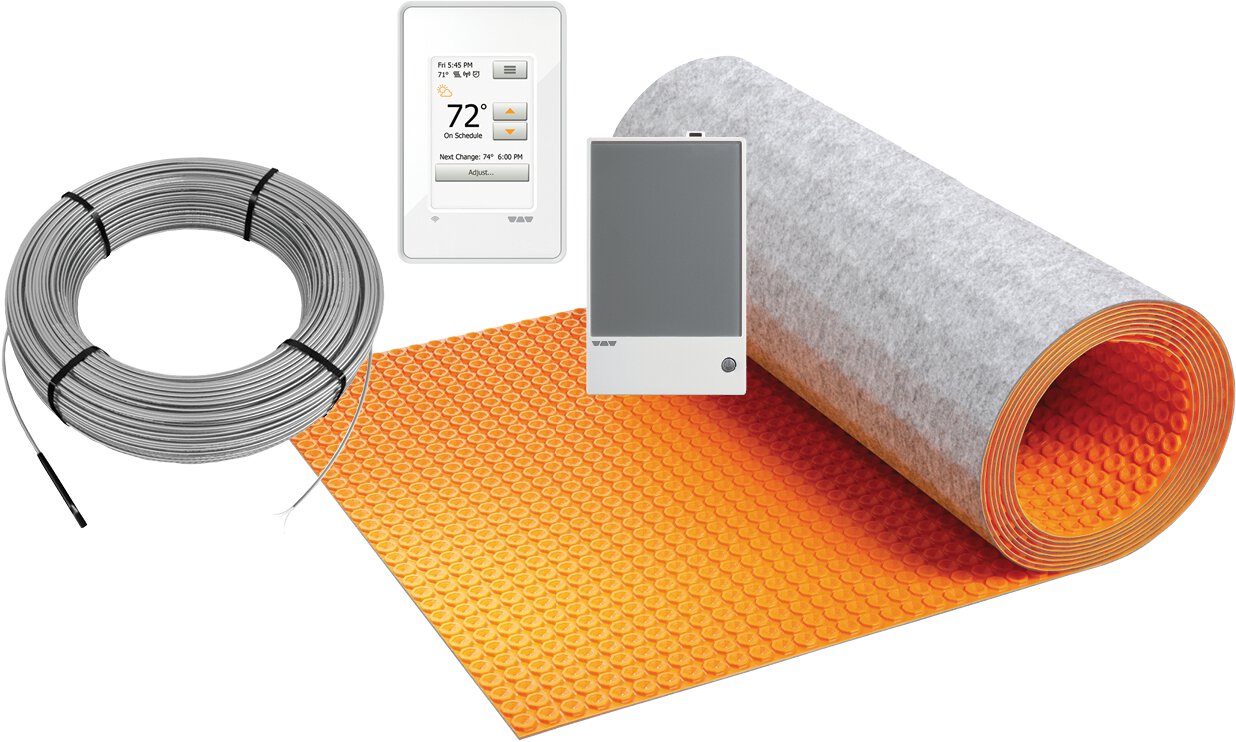

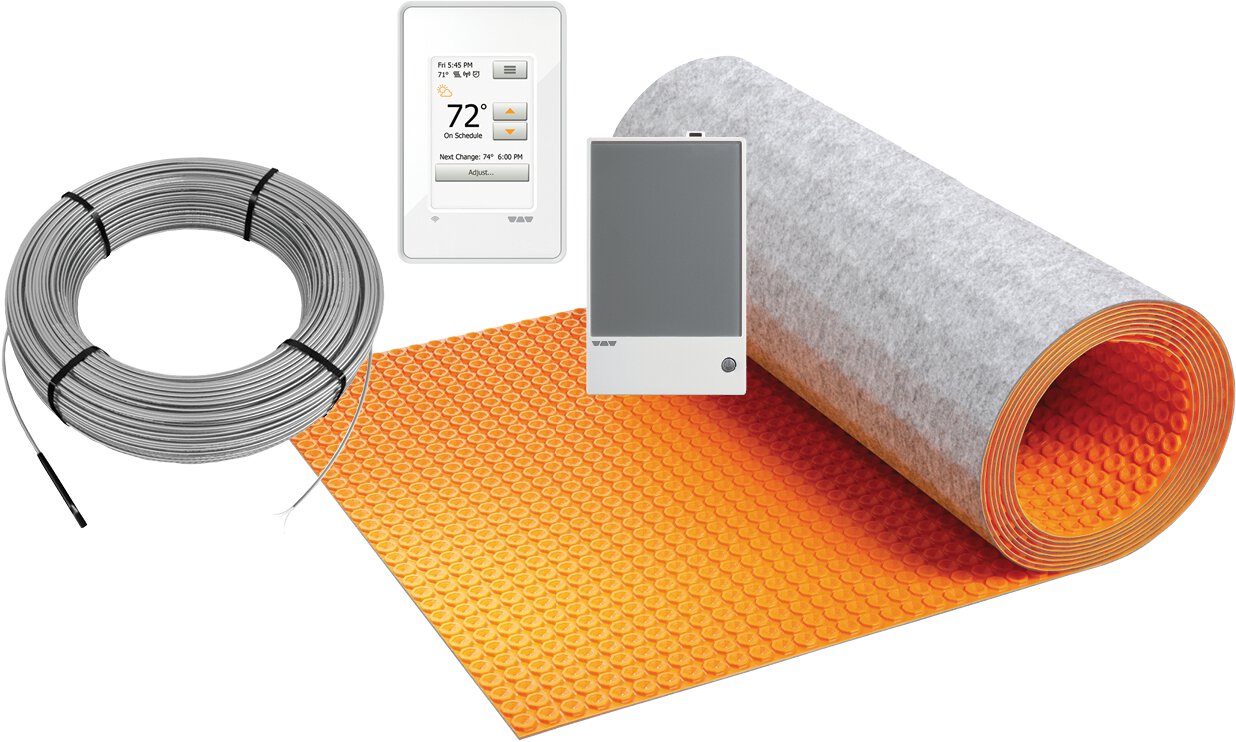

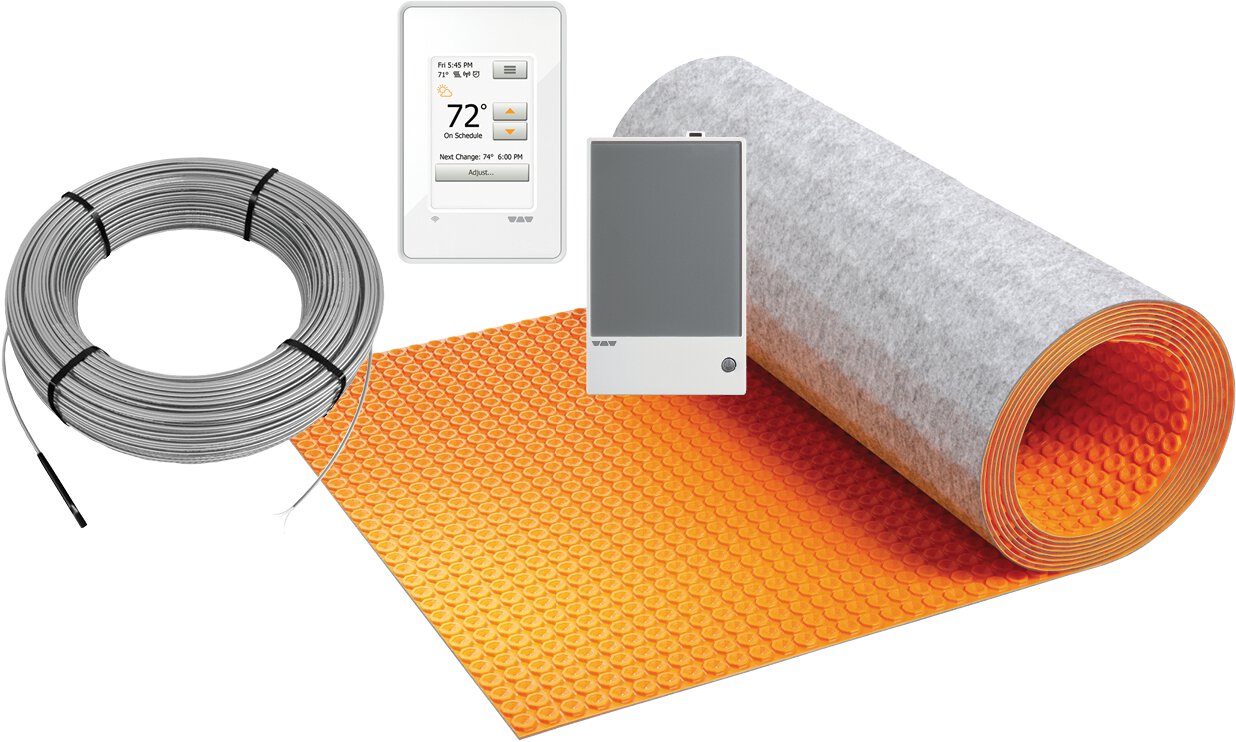

Products used