Schluter®-DILEX-EDP

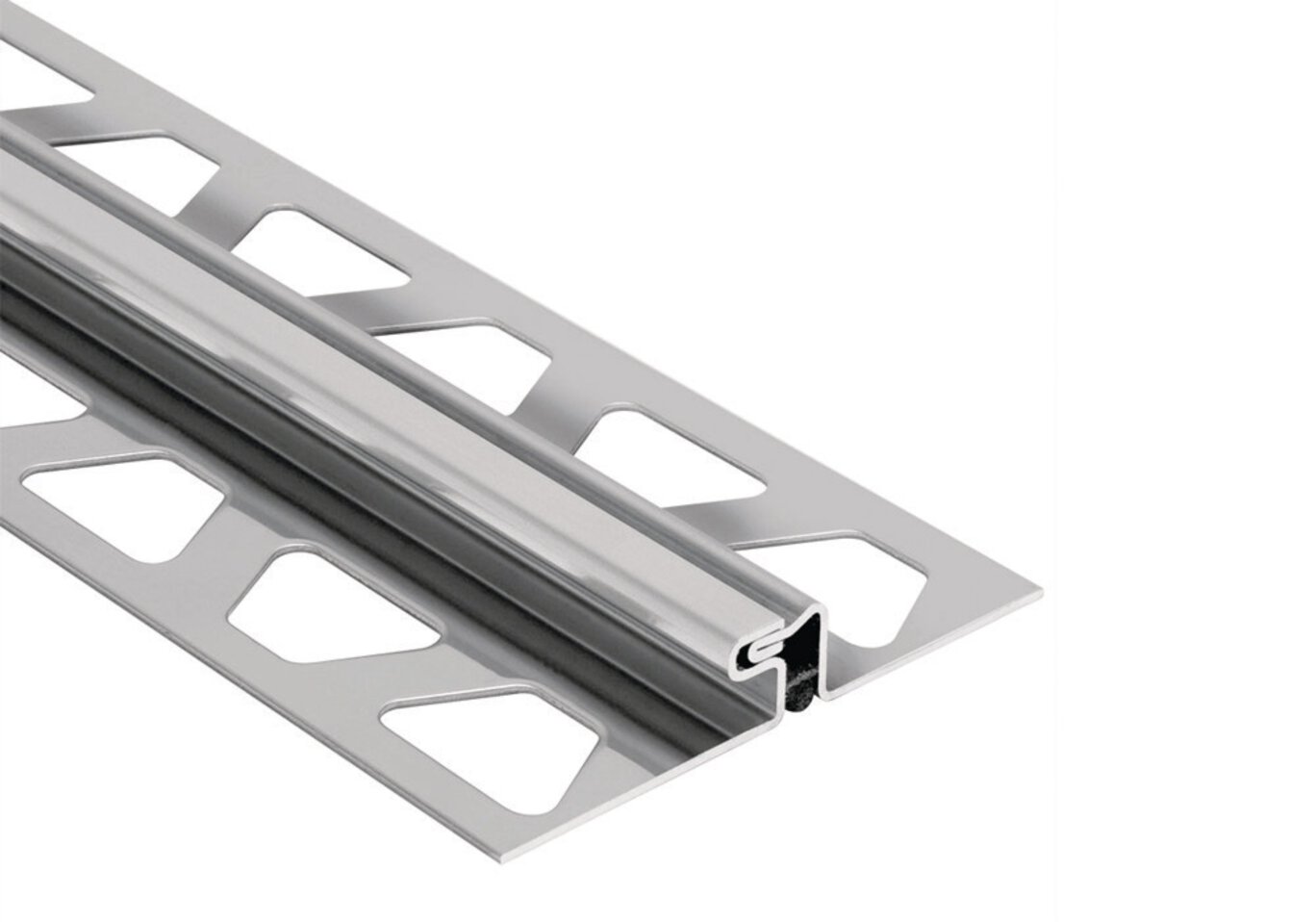

Surface joint profile with tongue-and-groove movement zone

- Designed to allow movement and reduce stress in large, tiled areas

- Eliminates the need for caulking

- Prevents cracking and delamination of tiles

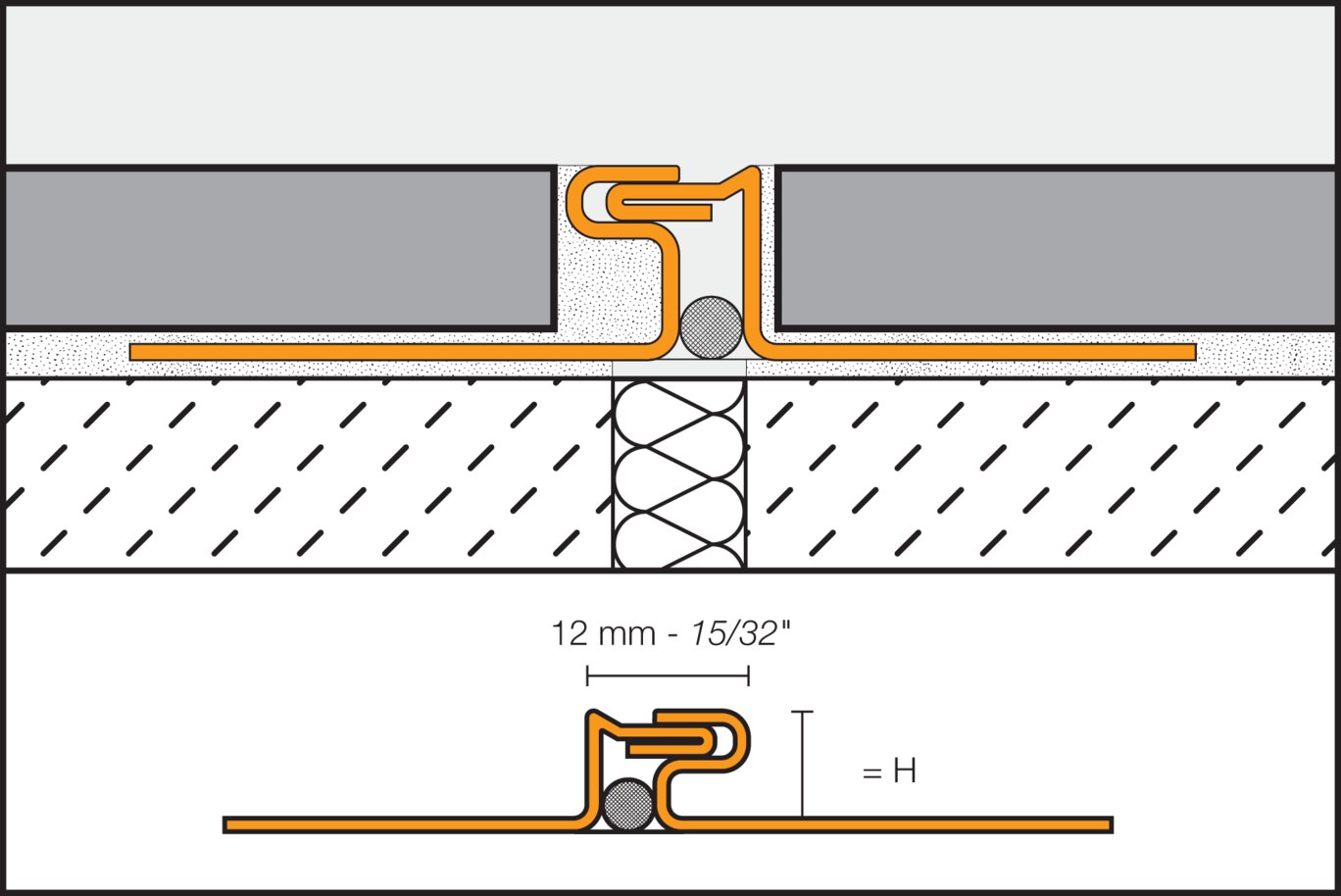

- Accommodates horizontal movement via the 15/32" (12 mm)-wide stainless steel tongue-and-groove connection, which forms the visible surface

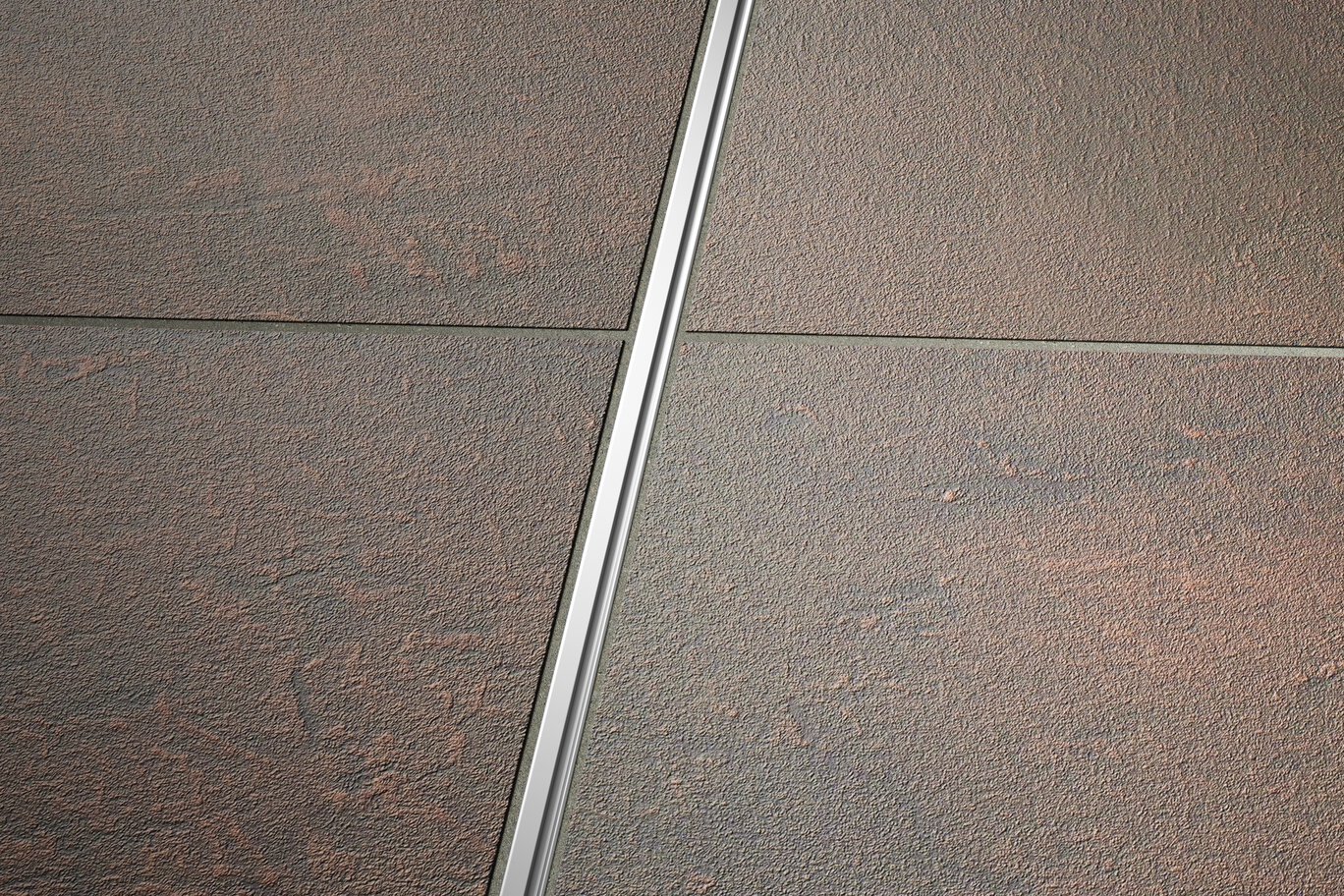

- Designed for tile surfaces subject to heavy use, including vehicular traffic

- Can also be used on floor surfaces maintained with cleaning machines

- Available in stainless steel

Find recommended accessories here

Profile Estimator

Discover what you need for tile protection and easy transitions.

Schluter®-DILEX-EDP features trapezoid-perforated anchoring legs, made of stainless steel, which are secured in the mortar bond coat and provide edge protection for adjacent tiles. The profile separates individual fields in the tile covering and accommodates horizontal movement via the stainless steel tongue-and-groove connection, which also forms the visible surface. Because the profile is designed to absorb horizontal movement only, appropriate measures must be taken to prevent the screed from moving vertically. In its base position, the visible width of the DILEX-EDP profile is 15/32" (12 mm). The profile is particularly suited for tile surfaces subject to heavy use.

DILEX-EDP offers secure edge protection for surfaces exposed to continuous vehicular traffic and is, therefore, suited for use in production plants, warehouses, shopping centers, and underground parking garages, or for floor surfaces maintained with cleaning machines.

DILEX-EDP requires no special maintenance or care and is resistant to mold and fungi. Clean profile using common household cleaning agents. Stainless steel surfaces exposed to the environment or aggressive substances should be cleaned periodically using a mild household cleaner.

Regular cleaning maintains the neat appearance of stainless steel and reduces the risk of corrosion. All cleaning agents must be free of hydrochloric and hydrofluoric acid and chlorides. Stainless steel surfaces develop a sheen when treated with a chrome-polishing agent.

1. Select the profile according to the tile thickness and format.

2. Using a notched trowel, apply thin-set mortar over the area where the profile is to be placed. The profile must align directly with movement joints in the substrate below.

3. Press the perforated anchoring legs of the profile into the mortar and align.

4. Trowel additional thin-set mortar over the perforated anchoring legs to ensure full coverage and support of the tile edges.

5. Solidly embed the tiles so that the tiled surface is flush with the top of the profile; the profile should not be higher than the tiled surface, but rather up to approx. 1/32" (1 mm) lower.

6. A joint of approximately 1/16" - 1/8" (1.5 - 3 mm) should be left between the tile and the profile.

7. Fill the joint completely with grout or setting material.

Product Table

FAQ

How do I cut profiles?

Schluter™ profiles are available in a variety of different materials , so methods for cutting vary. Below are best practices for cutting according...

Read more

Watch & Learn

About the product

Introduction to Schluter® Profiles

Tips on How to Choose Your Profile Size in Relation to Your Tile

Tips on Cutting Profiles

Find some existing tutorials and project documentation videos to learn how-to get the best out of our products - for more fun in your life, start now!

Watch more videos / playlists